Does your house need new hardwood floors?

Hardwood Flooring

Domestic Hardwood

North American hardwoods offer a classic, warm appearance. You’ll generally find them at a lower price point than exotic hardwoods. Common domestic hardwoods are red oak, white oak, hickory, North American cherry, North American maple, black walnut, douglas fir, beech, and ash.

Red Oak

Quercus rubra

Red Oak is a hardwood. It has an open grain and is slightly pink in hue.

Janka Hardness: 1290

White Oak

Quercus alba

White Oak is a hardwood. It has a tighter grain than Red Oak and has a golden hue.

Janka Hardness: 1360

Beech

Fagus grandifolia

Beech is a hardwood with fine grain and a reddish light tan color that sometimes has a silvery sheen. Color variation between boards can be significant.

Janka Hardness: 1300

American Cherry

Prunus serotina

American Cherry is a moderately hard wood more commonly used for borders and accents than for entire floors. It is light sensiteve and will darken significantly when first exposed to light.

Janka Hardness: 950

Hickory

Carya

A hard wood with a distinctive character and colors ranging from pale white to chocolate.

Janka Hardness: 1820

Southern Yellow Pine

Pinus palustris

One of the softest woods used for flooring. It has a golden yellow hue. The grain is usually straight, sometimes irregular, and the texture is commonly medium and uneven.

Janka Hardness: 870

Sap Hard Maple

Acer saccharum

Hard and durable wood. Has a distinct light color, popular to achieve a modern look. Commonly used for gym floors.

Janka Hardness: 1450

Birch

Betula alleghaniensis

Hard and durable wood. Sapwood is a creamy yellow and heartwood is light reddish brown. It has slightly lower natural luster than most other species.

Janka Hardness: 1260

Douglas Fir

Pseudotsuga menziesii

One of the softest woods used for flooring. Yellowish tan to light brown. Color changes dramaticly with exposure to sunlight.

Janka Hardness: 660

Ash

Fraxinus americana

Hard and elastic. Creamy white sapwood with light tan heartwood. Bold grain and coarse texture.

Janka Hardness: 1320

American Walnut

Juglans nigra

Slightly softer wood than Oak. The light sapwood contrasts with the dark heartwood that ranges from chocholate to puple-ish black. Grain is wavy.

Janka Hardness: 1010

Available Cuts

Plainsawn

This method of cutting produces the widest boards and is the most economical. The wood expands and contracts more with moisture and temperature changes. Not recommended over radiant heating.

Quartersawn

The logs are cut in quarters and then the boards are cut at 90 to the growth rings. This produces tight clean vertical grain with fleck pattern. More stable floor since the wood contracts and expands vertically.

Riftsawn

Similar advantages as quartersawn. It does not have the fleck patterns that are characteristic of quartersawn wood.

Quartersawn / Riftsawn

Includes both types of cuts (see profiles above). This option is more economical than riftsawn only or quartersawn only.

Exotic Hardwoods

Hardwoods found outside North America are commonly known as exotics. Imported from places like Brazil, Africa, the Far East, and Australia, exotic hardwoods often feature less common colors and unique graining. Popular exotic hardwoods include Brazilian cherry (also known as jatoba), teak, ipe, santos mahogany, tigerwood, merbau, cumaru, wenge, Patagonian rosewood, zebrawood, African mahogany.

Brazilian Cherry (Jatoba)

Brazilian Walnut (Ipê)

Brazilian Teak (Cumaru)

Afrormosia – 1560

Amendoim – 2090

Angelique – 1290

Ash, Silky – 1460

Ash, Victorian – 1010

Ash, White – 1320

Bamboo, Carbonized – 1120

Bamboo, Natural – 1400

Beech, European – 1300

Bloodwood – 2900

Brushbox, Northern – 2045

Bubinga – 1980

Cherry, Andean – 2820

Cherry, Bolivian – 3190

Cherry, Brazilian – 2820

Cherry, Caribbean – 3100

Cherry, Chilean – 990

Cherry, N. American – 950

Cherry, Patagonian – 2820

Cherry, Salinas – 3190

Chestnut, Patagonian – 1610

Chestnut, Southern – 2670

Chestnut, Sweet – 540

Cypress, Australian – 1375

Cypress, Bermuda – 1375

Doussie – 1770

Ebony, Striped – 1650

Gum, Red River – 1410

Gum, Sydney Blue – 2025

Iroko/Kambala – 1260

Jarrah – 1915

Kempas – 1710

Lacewood – 840

Mahogany, Andean – 3840

Mahogany, Honduran – 800

Mahogany, Royal – 1400

Mahogany, Santos – 2200

Mani – 1400

Maple – 1450

Maple, N. American – 1450

Maple, Patagonian – 1500

Merbau – 1925

Nogal, Nicoyan – 1700

Oak, Red – 1260

Oak, White – 1360

Orosi – 3540

Padauk, African – 1725

Palm – 1500

Palo Blanco – 680

Palo Rosa – 1732

Pine, Heart – 910

Purpleheart – 2090

Rosewood, Bolivian – 1780

Rosewood, Caribbean – 2300

Rosewood, Honduran – 2200

Rosewood, Patagonian – 3840

Rosewood, Striped – 1650

Saddlewood – 1420

Santa Maria – 1150

Shedua-Mutenye – 1650

Sucupira – 2140

Tamarind – 3000

Teak, Brazilian – 3540

Teak, true – 1155

Tigerwood – 2160

Timborana – 1570

Walnut, Brazilian – 3680

Walnut, Caribbean – 1400

Walnut, N. American – 1010

Walnut, Patagonian – 2800

Walnut, Peruvian – 1080

Walnut, Tiger’s Eye – 1650

Wenge – 1630

Zebrawood – 1575

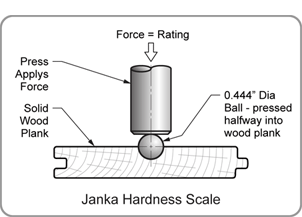

Hardness Rating

This rating determines a floor’s practical durability. Softer woods at the lower end of the spectrum are recommended for areas with very light traffic, while highly–rated hardwoods can stand up to much more wear and tear. Janka ratings are measured in pounds–force (lbf), with the highest ratings able to stand up to heavy force without denting. The test measures how many pounds of force it takes to drive a .44″ diameter steel ball halfway into the plank of wood that’s being tested.

High: You’ll find the really tough hardwoods in this category, including ipe, Brazilian cherry, cumaru (Brazilian teak), mesquite, Santos mahogany, merbau, and jarrah. Encompassing ratings from 1800–2400, these hardwoods are good for every application from high–traffic businesses to homes with kids, pets, and heavily–used rooms.

Medium: Filling in the middle ground of the Janka Scale, hardwoods rated between 1200 and 1800 are good for most normal residential applications. This level offers such popular hardwoods as, red oak, white oak, maple, American beech, ash, white oak, Australian cypress, and yellow birch.

Low: Ratings which fall in the 600–1200 range are best for low–traffic areas like bedrooms and closets. Low–rated woods include Douglas fir, southern yellow pine, black cherry, teak, and black walnut.

Engineered Hardwood Flooring

Engineered hardwood flooring has two major types of construction, mutli–ply and three–ply. Multi–ply is constructed with a plywood core consisting of 5–11 plys, with a top layer, called a veneer, of the finished wood. Three–ply is constructed with three total layers: a balance sheet, core layer and the top veneer. The balance sheet is usually the thickness of a single ply of plywood, while the core layer is a solid piece of wood. The top veneers of engineered hardwood floors are manufactured using one of the following two methods:

Rotary Peeled: Rotary peeled veneers are created by rolling the log on a machine while a blade peels away a top layer. This process is usually done for thinner veneers of 1/8″ and under.

Sawed: Sawed veneers are created by sending pieces of lumber into a cutting machine that slices the lumber into veneers. This process is usually used on veneers that are 1/8″ and thicker.

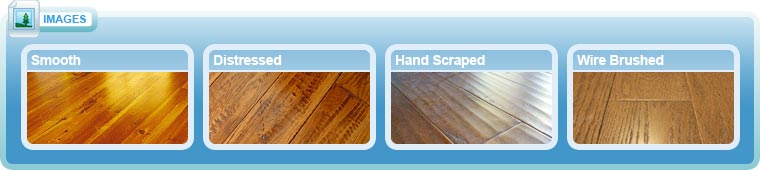

Textures

Smooth: This is the most commonly seen hardwood floor texture, or lack thereof. It is simply a smooth finished surface.

Distressed: Factory distressed hardwood floors are worn and distressed by hand, sometimes with the aid of a machine, giving your hardwood flooring a well–used look. Distressed hardwood floors bring a warm, lived–in look to any room

Hand–scraped: hardwood pieces are individually scraped by hand, giving your hardwood floor a naturally worn, distressed appearance. No two planks will look alike, so if you’re after a unique, antiqued look for your floor, hand–scraped may be the way to go. Since this must be done by hand, it can be costly. Machine scraping can be done, but it will look machined, and will lack the random pattern of hand–scraped hardwood flooring. The terms “distressed” and “hand–scraped” are sometimes used interchangeably, but there is a difference. Distressed hardwood floors have a “beaten” appearance while hand–scraped hardwood flooring is attempting to mimic a more naturally time worn look.

Wire brushed: Sapwood is removed by wire brushing, bringing out the wood grain for a grainy effect and feel. This texture is gaining popularity.

Widths

Strip: Hardwood strip flooring consists of boards less than 2 1/4″ wide. This is the most popular type of hardwood flooring, and is great if you want to make your room look bigger.

Plank: hardwood pieces are wider than 2 1/4″, and are great for larger areas.

Colors

While color will always be an important concern when buying flooring, keep in mind that hardwood floors can be stained to achieve the look you want.

Light: Light shades bring brightness to a room. Popular light hardwood floors include maple, white oak, red oak, and hickory.

Medium: Some colors fall squarely between light and dark, bringing easy warmth to a space. Naturally medium–toned hardwood floors include Brazilian cherry, sapele, tigerwood, and teak.

Dark: Perfect for creating a sense of coziness and comfort, dark hardwood floors are also a popular choice for heavily–trafficked rooms. Look for hardwoods like black walnut, ipe, and wenge.

Grades

Clear: Also known as “first” wood, clear grade hardwood flooring is free of visible defects, with little color variation and no knots.

Select: Select, or “second” grade hardwood flooring, features minor knots and some variation in color.

Common: “Third” grade hardwood floors offer a more rustic appearance with knots, natural color variations, dark graining, and other visual imperfections. #1 common and #2 common varieties are available.

Rustic/Tavern: This grade of hardwood floor offers a rustic look with multiple visual imperfections like knots and dark graining.

Exotic: Many exotic hardwood flooring goes by different rating systems depending on where they’re manufactured. They will often have their own unique rating systems, so if you have a question about an exotic hardwood’s rating, ask the retailer before you buy.

Hardwood Floor Design

Parquet: Rectangular blocks of wood are geometrically aligned, creating an attractive, classic pattern. Parquet floors are generally glued down. The most popular size is 6″x6″ and 5/16th” thick.

Inlay: An inlaid border or medallion pattern for the middle of the floor can make your hardwood floors a true statement piece in your home. Pre–existing hardwood floors can also have a thin inlay installed over them.

Stenciled/Stained “inlay”: This process is as simple as taping a pattern onto a pre–stained floor and staining a darker or lighter stain over it. When the tape is peeled away, a beautiful pattern emerges. While a skilled floor refinisher can easily handle the task of staining your hardwood floors for an inlaid appearance, it may also be possible to accomplish this yourself with a steady hand. Wood pegs and old iron fastenings can also be simulated with this look.

Mixed media: Like the look of marble, even though you’re choosing a hardwood floor? Mixed media floors combine the best of both worlds, adding beauty to your hardwood floors with inlaid marble, ceramic tiles, brass, aluminum, copper, stainless steel, and almost any other material you’d want to accent your hardwood floors.

Edges

Micro bevel/eased edge: Each plank has the corners cut at a 45 degree angle, creating a very small groove between aligned planks.

Bevelled: The corners of each plank are cut at a more extreme angle, adding visual interest with a deep V where the planks meet. This type of edge is usually seen in irregular hardwood flooring.

Square edge: These planks line up to form a continuous surface with no obvious edges.

Distressed: Each edge has some slight irregularity, matching the distressed or hand–scraped look of the planks.

Hardwood Floor Finishes

Unfinished: If you’d rather sand, stain, and finish your hardwood floors yourself, an unfinished floor is the way to go. Unfinished hardwood floors are best if you’re trying to match an existing floor.

On–Site: These finishes are applied after the unfinished hardwood flooring is installed. While most homeowners hire a flooring professional to install and finish hardwood flooring, it can also be done by the savvy Do–It–Yourselfer.There are several types of finishes that can be used, including wax, oil, and urethane.

Prefinished: Prefinished hardwood floors have been finished at the factory, eliminating that step from the installation. Most flooring manufacturers use three to ten coats of UV finish , sometimes with aluminum oxide added to extend the life of the finish. These hardwood floors are best if you’re looking to spend a little less money and save some time, or if you want to install floating floors. A general rule of thumb to follow is that low gloss or matte finish floors suit high–traffic areas, and higher gloss finishes are best in low–traffic spaces. These are the two categories of hardwood floor finishes:

Penetrating finishes: This type of finish is so named for how it sinks into the wood. This category covers sealers and resins, as well as oil finishes like tung oil and linseed oil.

Surface finishes: These finishes are layered atop your wood floor, similar to paint. Polyurethane (urethane), lacquer, varnish, acrylic, epoxy, wax, and shellac are all surface finishes.